milling

Upon harvesting, coffee heads down to the mill. The milling process has many steps before the coffee fruit is converted into a raw bean that’s ready to be roasted.

Our origin operations include two mills, El Manzano and Tequendama, which allows us to optimize our coffee’s processing and maintain our high traceability and quality standards.

Coffee milling has many steps and varies depending on the preferred processing method. Join us for an in-depth look at our facilities:

El Manzano Mill

This state-of-the-art processing facility is located within Finca El Manzano. The wet mill has the capacity to process 10,000 bags and the dry mill has the capacity to process 25,000 bags. At EL Manzano, coffees can undergo various processes such as: patio, raised bed and mechanical drying, as well as natural, honey, and fully washed processing methods.

Tequendama Mill

Our Tequendama Mill is located within Finca Las Isabellas and has the capacity to process up to 5,000 bags at its wet mill, where processing undergoes strict standards to ensure the quality and traceability of each lot. Tequendama and its surroundings are filled with rich biodiversity, which creates ideal climate conditions that allow coffees to undergo various processes such as: patio, raised bed and mechanical drying as well as natural, honey, and fully washed processing methods.

Processing Methods

Natural: During this process, coffee cherries are washed of dirt and debree from the farm, and transported directly to our patios. Coffee remains intact inside the fruit skin for the entire drying process, which takes on average 12-14 days.

Semi-Washed: Coffee cherries are washed and depulped, transported to a machine that uses high water pressure to wash off the mucilage from the parchment layer of the coffee bean. From there, coffee is spread out on our patios to dry for around 8-10 days.

Pulp Natural: These coffees are washed and depulped. However, unlike semi-washed coffees, the coffee is left with a layer of sugary mucilage surrounding the seeds and then laid out in our drying patios for 10-12 days.

Fully Washed: Coffee cherries are washed and depulped. The parchment coffee is submerged in water for 16-24 hours until the mucilage layer is broken down and washed off the bean. From there, beans are rinsed and spread on the patios to dry for 7-10 days.

Wet Mill

Wet milling is the process of washing the coffee fruit and seed in preparation for the drying process. During this process, coffee goes through six steps:

Mechanical Siphon: This machine acts as a screen, sorting and washing coffee cherries before separating them into sinkers and floaters.

Bucket Elevator: The coffee is then transported to the unripe bean separator through a vertical belt known as bucket elevator.

Unripe Bean Separator: At this point, the separator rejects any cherries that are not fully ripe, cycling them back to the floaters to continue processing.

Vertical Depulpers & Rotating Screen: The ripe cherries then go through the depulper and rotating screen, where pulp, oversized and deformed beans are filtered out.

Fermentation Tanks: Once the highest quality beans have been sorted, they are placed in fermentation tanks. These tanks are filled with water and hold the depulped coffee for 12-24 hours until the mucilage has naturally broken down and dissolved from the bean.

Mucilage Remover: From the fermentation tanks, the coffee passes through a perforated cylinder within the machine, where water and friction are used to cleanse the outer parchment from any remaining mucilage.

Drying

Drying is one of the most crucial processes prior to storing coffee. Prior to drying, coffee beans contain up to 60% moisture content, so it’s necessary to reduce this in order to be able to store coffee for longer periods of time while maintaining it’s sensorial and quality attributes. This process can be either done naturally or mechanically:

Natural Drying Method: During this process, unprocessed coffee beans are laid out either in patios or raised beds to sundry. At this point, the coffee is raked every hour between 8:00 am and 4:00 pm to ensure homogenous drying, sun exposure and airflow. The average drying time with this method is 7-14 days on patios and 10-14 days on raised beds, depending on weather conditions.

Vertical & Horizontal Mechanical Drying: For the mechanical drying process, coffee is pre-dried for 2-3 days on our patios before being loaded into the drier. Inside, parchment coffee is heated by hot air created by furnaces burning coffee husk. The coffee circulates through the vertical drum once per hour at 35-45° C, for around 2-3 days after pre-dry.

Once the drying process has finished, the beans should have an internal moisture content of 10-12% to prevent the development of mold and bacteria, while maintaining enough moisture so that the bean doesn’t break during further processing.

Dry Mill

Once the coffee has dried properly it’s taken to our dry mill, where it goes through a series of screening and grading machines to remove the parchment:

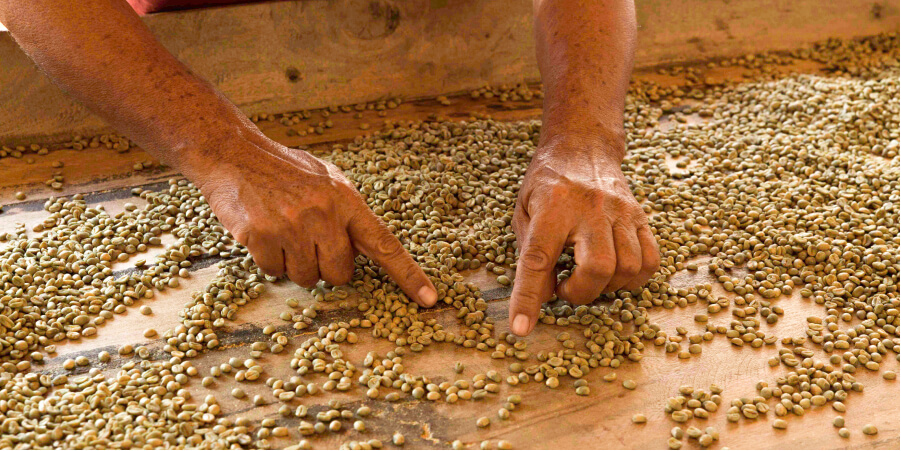

Parchment Remover: Parchment is screened, before passing through a rotating metal disk that uses friction to separate the parchment from the green coffee. Parchment is then pulled out of the machine by a vacuum, while the green coffee is channeled out of the machine.

Density Grader: Once parchment is removed, the green coffee is sorted by density to determine the integrity of the bean. From there, it’s loaded into a long metal surface positioned at a five to ten degree slope and fixed with small grooves that allow air to pass through. As coffee vibrates forward, less dense beans gravitate down the slope, while the densest beans gravitate up the slope.

Size Grader: Once coffee has been sorted by density, it’s time to sort by size. At this point, green coffee passes through a series of layered screens, each containing different sized perforations. The largest screen is positioned on top, and allows beans to fall through as they vibrate forward, filtering smaller beans onto their respective size screens. Every size is channeled into separate chutes in preparation for color sorting.

Color Sorter: This is the final step in green coffee grading, which allows us to filter out any off-color beans. The color sorter uses high scan cameras to reject impurities as the coffee passes through the machine.

Once this process is complete, the bean is now the “green coffee” that we ship out to our clients and partners.

Quality Control

Our quality control protocols help us evaluate our production, processing, and commercialization efforts. Prior to entering our mills, coffee cherries are analyzed to evaluate maturation and sugar content, ranking them from “C” to “AA,” the latter one being the optimum quality. This helps us identify the ideal processing method to highlight and amplify the coffee’s attributes.

Quality control during processing varies depending on the method but, whether we depulp the cherry or opt for natural processing, we check for any noticeable damages to the coffee on a daily basis. Our attention to detail during this process increases when coffees are dried mechanically, since we have better control over variables such as airflow and temperature, and we want to prevent any damages to the bean.

Once coffee has dried to perfection we take it to the dry mill for our team to process it and prepare it for a physical analysis of the bean, which allows us to identify any defects and sort coffee depending on density, size, and color.

Once this process is complete, we proceed to roast a 150 gram sample from every lot. From there, we wait up to 24 hours and cup every single coffee that comes out from our mills. It is at this point where we select the finest coffees we’ll be offering our clients throughout the year.